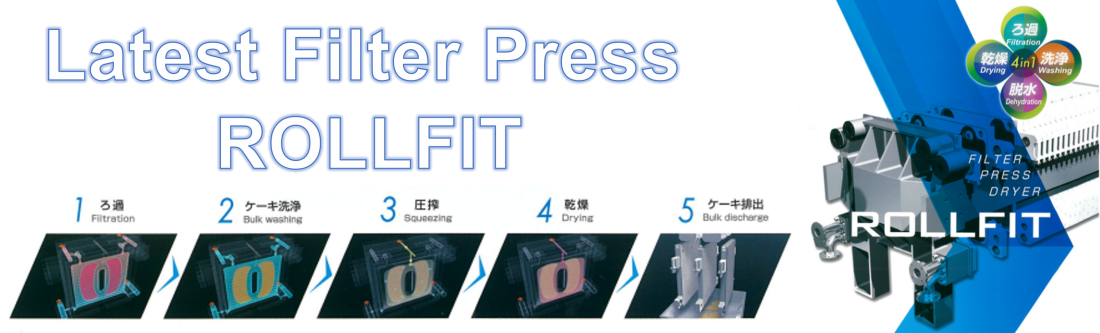

ROLLFIT Type

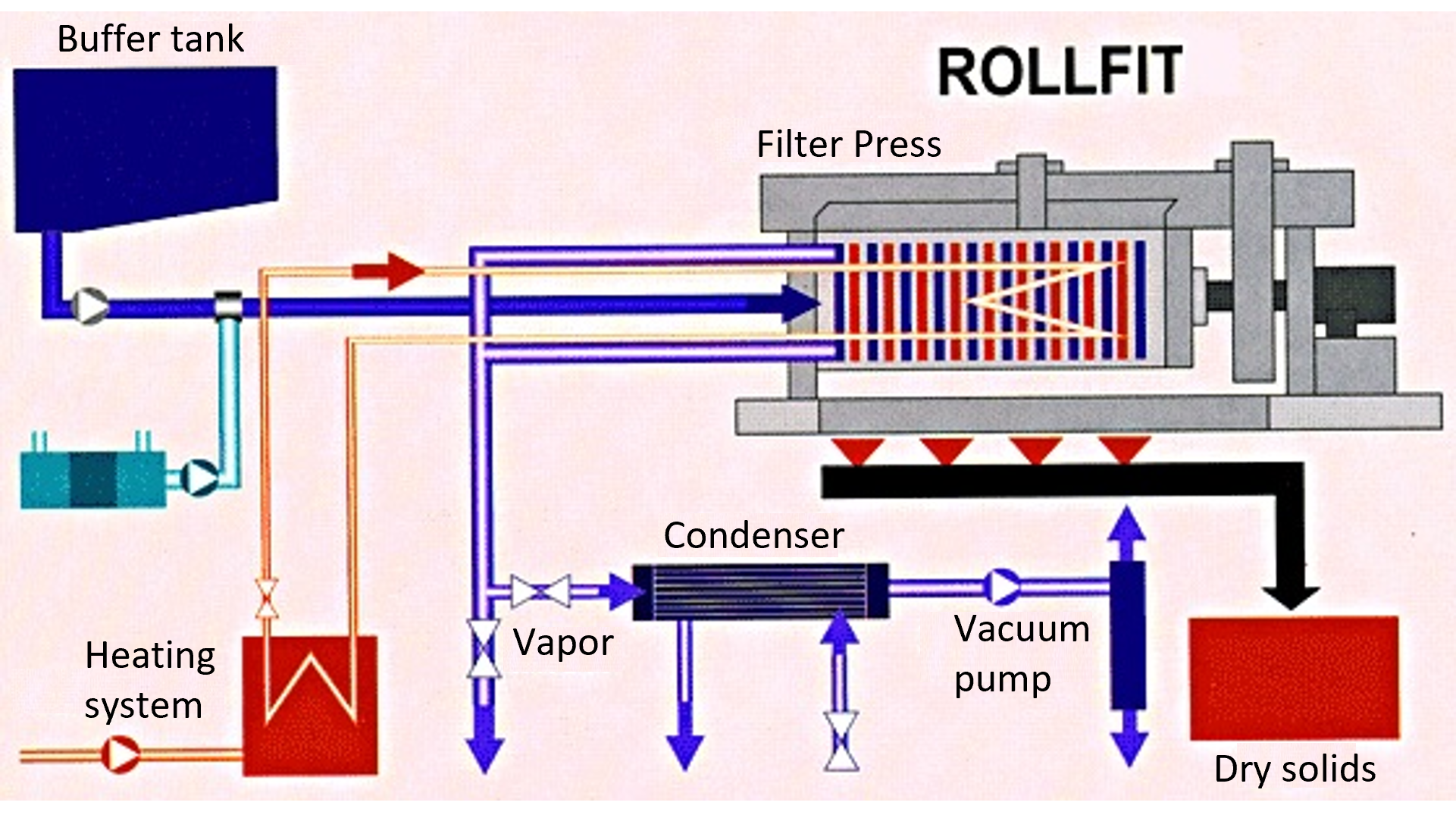

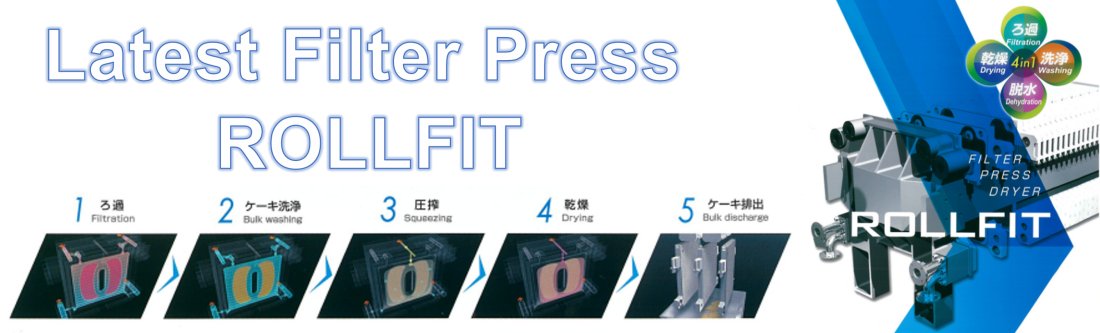

Filter Press with drying function「ROLLFIT type」is developed with Reisser Eilers&Partner AG in switzerland. ROLLFIT is new type machine combined conventional filter press and dryer.

Filter Press with drying function「ROLLFIT type」is developed with Reisser Eilers&Partner AG in switzerland. ROLLFIT is new type machine combined conventional filter press and dryer.

Features

- 1Rollfit Filter Press accomplishes 4 process, filtration, washing, dehydration and drying.

Compare to conventional system, rollfit saves installation cost and installation space. - 2After drying process, moisture content may reach less than 1%.

- 34 process in same equipment lowers contamination risk.

- 4Easy to discharge and move cake after drying for any material (sticky, hard to dry and so on)

- 5No need to wash filter cloth because cake can be completely discharge after drying.

- 6Vacuum (negative pressure) drying process lowers boiling temperature.

Drying process under low temperature is suite to heat vulnerable material. - 7In case of middle temperature heat source, may save running cost.

Use

- 1●Production Line

Metal material (nickel hydroxide, calcium carbonate, magnesium silica-based ceramics and so on), toner, organic pigment, electrode for battery

- 2●Industrial Waste Water Facility

- 3●Public Water Treatment Facility

ROLLFIT Process

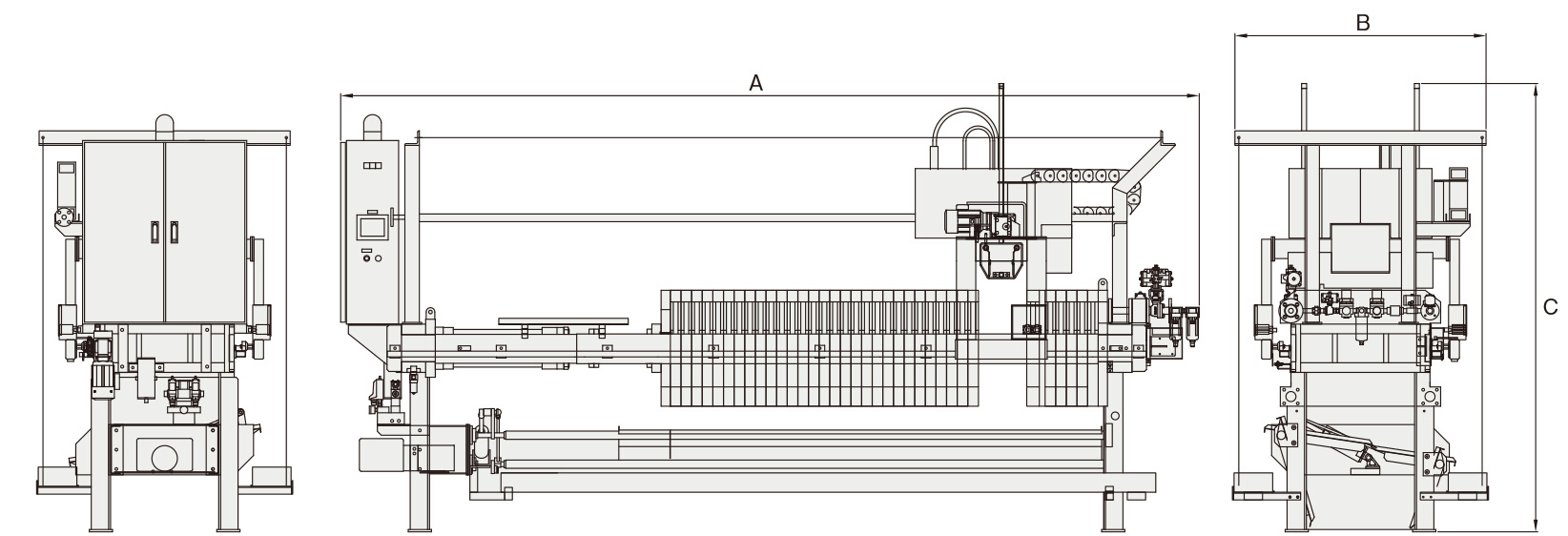

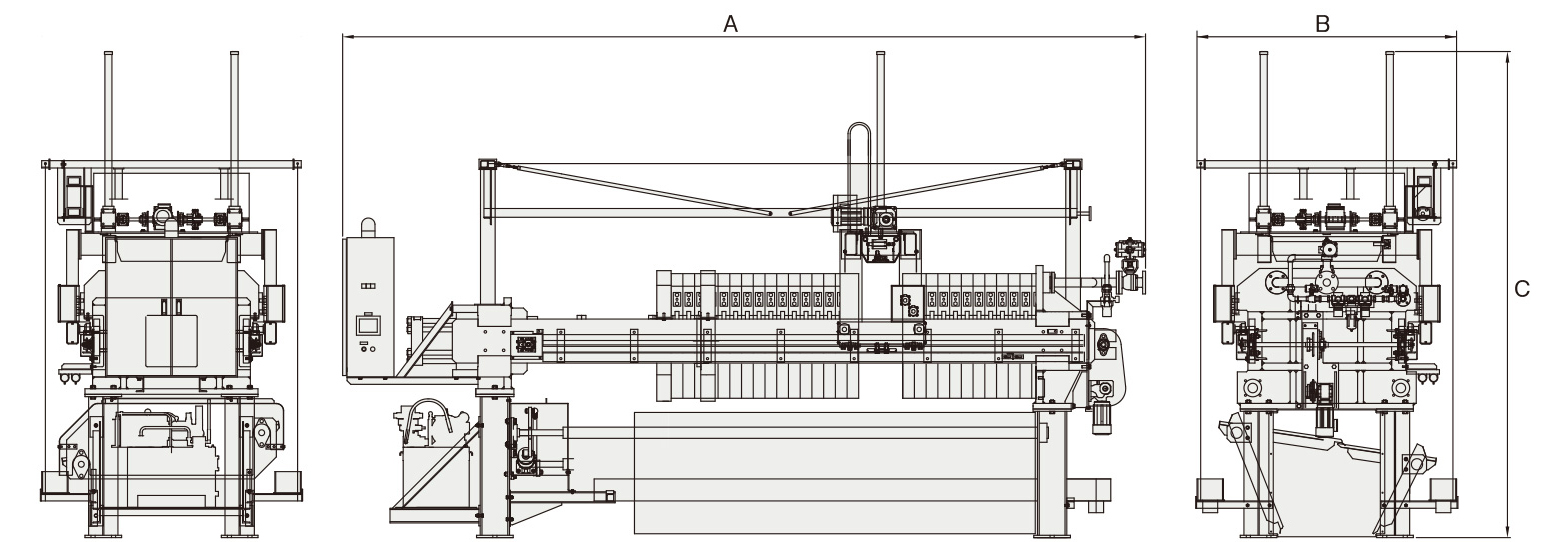

ROLLFOT Type & Filtration Area/Volume

| Type:Plate size | Filtration area per 1 chamber [m2] / Filtration volume per 1 chamber [L] |

Range of filtration area [m2]/ volume [L] |

Max chamber |

|---|---|---|---|

| 3 Type:310mm | 0.10/1.25 | 0.1/1.25~0.5/6.25 | 10 |

| 6 Type:600mm | 0.50/6.25 | 0.5/6.25~10/125 | 20 |

| 10 Type:1,000mm | 1.48/17.0 | 10/115~74/850 | 50 |

| 12 Type:1,250mm | 2.24/28.0 | 50/625~156/1,950 | 70 |

| 15 Type:1,500mm | 3.50/43.7 | 100/1,250~280/3,500 | 80 |

AUTOPAC-PRO type is filter press combined AUTOPAC type with automatic filter cloth washing function.

AUTOPAC-PRO type is filter press combined AUTOPAC type with automatic filter cloth washing function.